New Laser Engraving Capabilities at Protomatic

Protomatic now has multiple options to match your laser marking and light-duty, special-material cutting applications.

Big power for small jobs

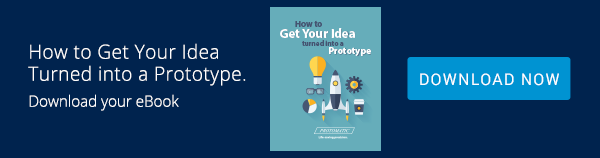

When your job calls for simple 2-axis engraving of anodized aluminum, stainless steel, or many types of plastic, Protomatic has you covered with our OMTech B10 laser engraver.

- Versatility combined with affordability.

- Standard 2-axis tabletop

- Blue 450nM,10W optical power

- Diode-based

- The power to cut through materials such as 5mm (.20″) black acrylic plastic or 8mm (0.31″) plywood in a single pass.

- Connect to a 400mm x 400mm positioning software for the ability to design, engrave and cut small parts with precision.

Omtech B10 laser cutting a “custom paint mask” made from yellow masking tape. The blue light is the actual laser beam.

Specialized laser precision

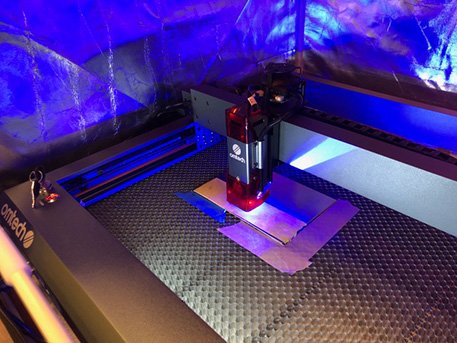

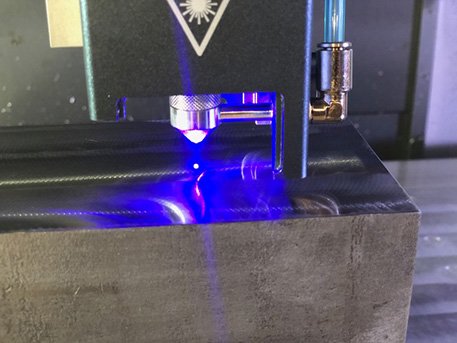

For a more precision industrial application, we repurposed a 16’’x 30’’ CNC machine set up for 3-,4-, and 5-axis work.

- Ideal for specialized laser precision marking

- Classic infrared (IR) fiber laser runs a 1064 nM

- Galvo-based beam deflector allows a longer field of focus — about 150mm (6”). This is a big plus if there is a feature in the way.

- The small 4-axis rotary table can be used for marking around a tube, or the CNC can mark the length.

For most applications we use the CNC machine, but Galvo provides 4” projection diameter reach for small parts. Since the IR Beam is invisible and not seen, a small red laser is used for beam calibration alignment.

IR Galvo-based laser setup for 4-axis marking.

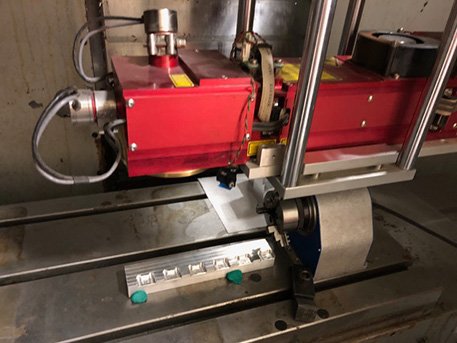

Large part marking

This setup is slightly confidential, but allows for complex marking with software.

- A 30”x 64” CNC

- Ideal for 2-,3-,4-, and 5-axis laser marking applications

- Allows laser marking with a 20W optical power 450nM blue laser

- Provides the precision of the CNC for location and rotation

2 axis laser marking application on stainless steel, 316SS alloy. Purge gas is used to keep lens clean during marking operation.`

A cut above

Protomatic is here to help with any of your laser marking and light-duty specialty materials cutting applications. Protomatic is a CNC precision machining shop specializing in prototype and short-run production components for the medical, aerospace, and other technical industries. Because of the critical nature of the parts we design and manufacture, the emphasis is always on Life-Saving Precision.

CONTACT US DIRECTLY. Phone 734-426-3655

- Scott Allen, Sales Manager Scott@Protomatic.com

- Lori Franz, Sales Lori@Protomatic.com

- Doug Wetzel, VP/GM Doug@protomatic.com

- Brian Heldt, Program Manager Bheldt@protomatic.com

About the author: Doug Wetzel is Vice President and General Manager of Protomatic.