Full inspection services

Protomatic offers full inspection services with CMM inspection capabilities on all of your dimensionally critical parts. Consistency is ensured with climate and dust-controlled manufacturing practices. Gauges are monitored using “GAGETrak” and are calibrated to NIST and/or ISO 10012 utilizing ISO 17025 qualified suppliers. Our inspection facility is used for in-house monitoring of manufactured goods as well as contract inspection projects. We are registered AS9100D & ISO 9001:2015, as well as ISO 13485:2016.

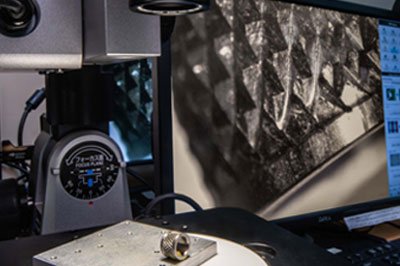

Protomatic has optical inspection equipment to help produce parts with exacting tolerances. The Micro Vu Spectra Comparator is a precision optical measurement device with interchangeable lenses typically ranging from 10X-20X, and is designed for small to medium-sized part inspection. Other vision systems are also available with even higher magnification.