A Guide to CNC Component Assembly Methods

Protomatic is a precision CNC shop specializing in prototype and short-run production components for the medical and aerospace markets. A key area of emphasis is our ability to apply the right methods for superior assembly operations. The following summary outlines our capabilities and is intended to assist you in selecting an integrated part manufacturing and assembly provider that meets your performance, quality, and compliance needs.

Types of Assembly

While basic assemblies may use fasteners or rivets, Protomatic offers a range of advanced assembly methods designed to enhance reliability, strength, and functionality. Our capabilities include:

• Fasteners — Screw and Bolt Assembly

We install screws and bolts to precise torque specifications, with or without thread locker. Common products include Loctite® 242, 243, 262, 271, 290, 609, and 680.

Fastener Assembly

• Rivets

We support both solid and blind rivet applications. Common solid rivets include MS-20426, 24470, 20613, and 35743. For blind applications, Pop-style rivets, blind bolts (NASM21140-1), and blind rivets (NASM20600-5) are used. Installations may be “wet” (with paint primer protection), “dry”, or “bonded” using polyurethane adhesives such as MMM-A-121. We also assemble with PEM® nuts, studs, standoffs, and captivated screws.

• Adhesives

Adhesive bonding is used for various assembly methods. Adhesive bonding with controlled bond gap thickness is typically used with epoxies. Other common adhesive materials include:

- Polyurethanes (MMM-A-121, MMM-A-132)

- Structural adhesives (Loctite® 416)

- Sealants (RTV 3145)

- Thermal-set glues

Adhesive Assembly

• Primers

We apply primers from trusted suppliers like PPG® and DeSoto® to improve bond strength and corrosion resistance. Examples include:

- MIL-A-46146

- MIL-PRF-23377

- TT-P-1757

• Mechanical Systems

Systems that use pre-tensioned springs are setup with specialized test conditions. Other systems may require dowel pins utilizing mechanical or thermal press-fit assembly methods (including ovens and/or liquid nitrogen).

• Special Components

Depending on the design, Protomatic also uses special components such as:

- Helicoils

- Keenserts

- Rivet nuts

- Nut plates

- Rivet studs

- Cable tie mounts

- Specialty tapes, Mastic, Hysol, and Loctite® sealants (#222, #545)

• Electrical, Pneumatic, and Hydraulic Assembly

Protomatic can wire for small machines and component assembly.

- Electrical assembly for coils, sensors, or motors

- Pneumatic and hydraulic assembly and testing

• Welding

We offer a variety of welding methods to meet strength and containment requirements:

- TIG, MIG, fusion, laser, and electron beam (E-beam)

- Integration ofsafety-wired nuts when appropriate

Welding Assembly

• Special Greases and Lubricants

We use industry-standard and specialty lubricants including:

- MolyCoat

- Anti-seize (Mil-PRF-907, AMS-2158)

- High-performance lubricants likeKrytox® 240AZ for final assemblies

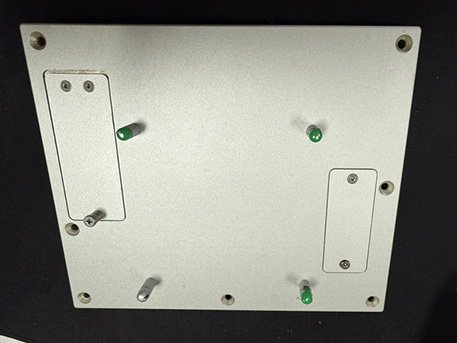

• Inspection and Testing of Final Assemblies

Every final assembly is verified through appropriate inspection and testing. These may include:

- Cosmetic and functional inspection

- Glue bond strength testing

- Electrical testing (voltmeters, other electrical equipment)

- Magnet polarity verification

- Visual inspections (vision systems, borescopes)

- Protective cover installation

We Put It All Together

From the initial product sketch to final assembly and testing, one thing remains constant: Protomatic’s commitment to delivering quality, efficiency, and Life-Saving Precision in every part and device we produce.

CONTACT US DIRECTLY. PHONE:

734-426-3655

- Walt Freeman, Sales Specialist – Walt@Protomatic.com

- Lori Franz, Sales – Lori@Protomatic.com

- Scott Allen, Sales Manager – Scott@Protomatic.com

- Doug Wetzel, VP/GM – Doug@Protomatic.com

- Kyle Helm, Program Manager – Kyle@Protomatic.com

About the Author

Doug Wetzel is Vice President and General Manager of Protomatic.