Advances in Laser Marking and Engraving of CNC Parts

At Protomatic, laser marking and engraving precision CNC parts has significantly evolved over the past few years.

Historically, lasers were limited to shallow “marking” operations because they lacked the power to “engrave” with depth. Today, thanks to advancements in laser technology, we can both mark (shallow engraving) and engrave (deeper cuts) to depth on most materials with high precision.

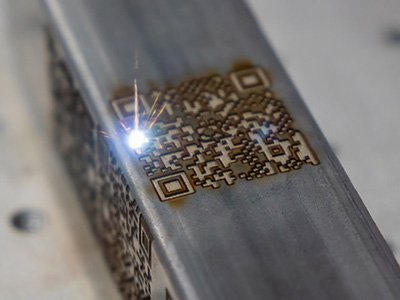

Data matrix on raw aluminum. We can perform deep marking of 0.010″ deep

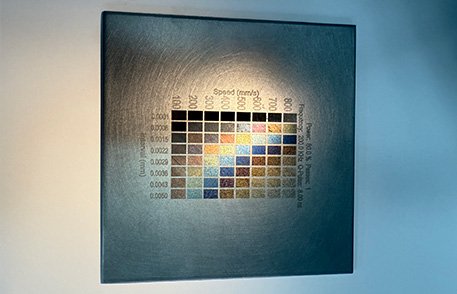

04SS Alloy with an example of new color marking technology.

Customer Specifications for Marking

Many prints simply state the type of marking that is required. However, many industries use a common spec developed by the aerospace industry — AS478 – Identification Marking Methods. This specification clearly defines all types of marking methods and the methods to be used when marking parts. Common markings are:

Common Marking Specification Callouts

- AS478-3B1 – Machine Engrave Shallow depth (0.003’’ max)

- AS478-3B2 – Machine Engrave Deep (0.006’’max )

- AS478-15B1 – Laser Engrave Shallow (0.0006’’ max)

- AS478-15B2 – Laser Engrave Intermediate (0.0006”min- 0.004’’max)

- AS478-15B3 – Laser Engrave Deep (0.010’’ max)

- AS478-35D – Bag and Tag

For Data Matrix/ UID Barcode Callouts

- Data Matrix per ECC200 in accordance with ISO-16022

- ISO-15434 for Coding Syntax

(Note: Unless otherwise specified, there is a quality testing default grade of “C” in the standard.)

- ISO-15415 – Automatic identification and data capture techniques (Bar Code) 2D symbols

- ISO-15418 – EAN/UCC Application Identifiers and Fact Data Identifiers

- ISO-15426 – Automatic identification and data capture technique Bar Code Verifier conformance spec for 2D symbols

- ISO-15434 – Automatic identification and data capture technique syntax for high capacity ADC media

- ISO-16022 – Automatic identification and data capture technique Data Matrix bar code symbology spec

- ISO-16388 – Automatic identification and data capture technique Bar Cod symbology spec Code 39

- MIL-STD-130 – Identification marking of U.S. military property

- BAC5307-1 – Part Marking of Machine Readable Information with label (Boeing proprietary spec)

Materials We Can Mark

Protomatic is set up to laser mark a wide range of materials. Historically, highly reflective materials were difficult to mark with laser due to the IR (Infrared) reflectivity, but with appropriate laser technology even these materials can be marked or engraved. While alternative methods like mechanical engraving or labeling are still used, laser engraving often provides the best quality and lowest cost.

Some common materials that can be laser marked:

Stainless, Super Alloys

Non-Ferrous – Aluminum

Red Metals – Brass, Bronze

Precious Metals—Gold, Silver, Platinum, Palladium

Refractory Metals– Tungsten, Niobium

Plastics- Acetel, Delrin, Ultem, PEEK, UHMW-PE

Laminants – Epoxy-based fiberglass grades G7,G10, G11; Cloth based (Micarta)

Other – Wood, Tapes

Types of Lasers in Use

At Protomatic, marking options are based on your needs. We use four core types of laser systems selected:

A. Fiber Laser (IR 1064nM 50w)

Ideal for fine surface marking, this galvo-based system enables rapid setup quick and CNC integration for larger, more complex metal engraving.

B. Fiber Laser (IR 1064nM MOPA 80w)

Designed for cutting thin sheets, deep laser engraving. Can mark on highly reflective material and enables color marking on stainless steels. Performs more complex markings for barcodes, data matrix and other specialty marking.

C. Diode Coupled – Blue (455nM- 20W)

This laser is fully intergraded with our 3-,4-,and 5-axis CNC milling machines and provides precision marking for metals and plastics. Especially useful for marking large parts, such as tubes with 4- and 5-axis applications.

D. Diode Coupled – Blue (455nM 10W )

This is a commercially available gantry-based machine for small sheet/parts approximately 400mm square (16’’). It is ideal for creating precision custom paint/glue masks for assembly work, protective films, cutting or engraving 2 axis parts.

Specialized Marking and Labels

We can also offer data matrix and barcode label printing using a high-resolution printer with specialty inks — fully compliant with specifications such as Boeing Aerospace Corp.® BAC5307. Our MOPA laser (Master Oscillator Power Amplifier) can provide color marking on stainless steel, black marking on anodized aluminum, and high-contrast text on plastic parts, making parts easier to read and identify.

Cutting

In addition to marking and engraving, our lasers can cut a variety of materials, we can cut:

- Soft materials — such as masking tape

- Wood — up to 3/8″ plywood in a single pass

- Thin metals

- Plastics

Qualification of Marking of Data Matrix

Protomatic has a special reader for grading the barcode and data matrix quality. These are letter graded from A thru F, with a standard pass grade of C or better. This rating system is based on multiple criteria — typically the lowest score, often “contrast,” determines the final grade.

Applicable standards and methods include:

ISO-15426 — Verification methodology

AIM DPM-1-2008 — Direct Part Mark quality guidance

ISO-15415 — 2D barcode decoding standards

ISO 29158 – 2D mark quality and technical requirements

AS9132 – Aerospace DPM verification standard

This specialized reader allows us to validate marks on both parts and labels, verifying the quality of the actual mark.

Summary

As this overview demonstrates, part marking is a detailed and critical process—especially in industries like medical and aerospace. Since most markings are permanent, precision and verification are essential. At Protomatic, we take pride in delivering markings that meet the highest standards for quality, and further our commitment to Life-Saving Precision in every part and device we make.

Contact Us Directly

Phone: 734-426-3655

- Walt Freeman, Sales Specialist-Walt@Protomatic.com

- Lori Franz, Sales –Lori@Protomatic.com

- Scott Allen, Sales Manager –Scott@Protomatic.com

- Doug Wetzel, VP/GM –Doug@Protomatic.com

- Kyle Helm, Program Manager –Kyle@Protomatic.com

About the Author

Doug Wetzel is Vice President and General Manager of Protomatic.