Maintaining CAM software for peak efficiency.

Computer Aided Machining software is very dynamic, with software companies bringing new programs to the market on a regular basis to fix bugs, provide quicker calculations for simulations, and improve tool-path algorithms.

This month, we want to share the strategies for maintaining CAM software that keep Protomatic at the forefront of the industry.

Some background

Protomatic was at the IMTS Show last fall, looking for ways to improve our manufacturing and maintain a competitive edge. We used our current software as a benchmark, then compared it to the new offerings available. Of course, costs are always a major consideration. It is important to keep in mind not only the initial software cost, but also additional training and validation costs.

The good news? Even with these costs, software is an inexpensive investment when you consider all that it can accomplish.

Buy new or upgrade

Is it better to buy new software, or keep a maintenance contract on current software? That is the question we asked ourselves as we were looking at the options.

Ultimately, we decided that keeping software current with maintenance agreements is often the more economical and efficient way to go. Software maintenance agreements typically come with an annual fee of 10%-20% of the newest software. And they allow Protomatic to keep the same technological edge provided with the brand new version.

Because of how quickly software companies improve on their technology, these agreements fit in with our strategy of keeping our software operating at peak efficiency. To us, annual maintenance plans just make good business sense.

Not all software tools are the same.

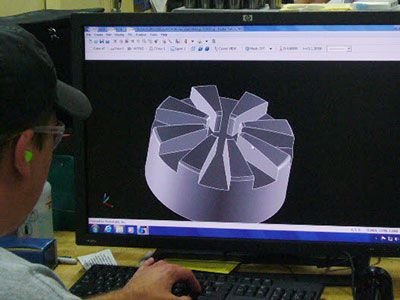

Different programs solve different problems, and it’s important to find the right tool for the objective. So we have several different software “tools” in our toolbox. In one case, we may need a 3-D contour-milling tool, and in another, 5-axis prismatic milling is the right solution.

Different CAM software packages offer different capabilities. We’re always looking for the ideal balance of optimum performance without paying for “bells and whistles” that we don’t need. That’s part of our strategy of maintaining costs and passing the savings on to our customers.

A total solution

Along with reviewing CAM software updates and new programs, we use our experience to incorporate other solutions such as part fixturing, method of manufacture, sequence of operations, and many others to optimize performance — and continue to bring “life-saving precision” to our customers.